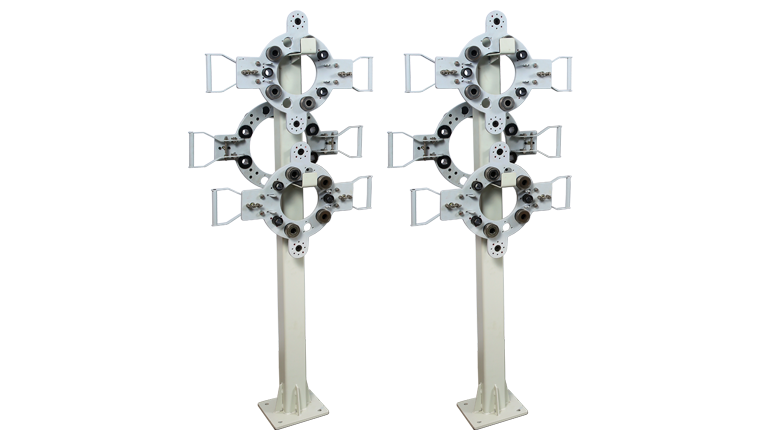

Designed & Developed exclusively for front axle Manufacturers to Pre-align Toe in a dynamic axle assembly line.

| Measurement Parameters | Range | Resolution | Accuracy |

|---|---|---|---|

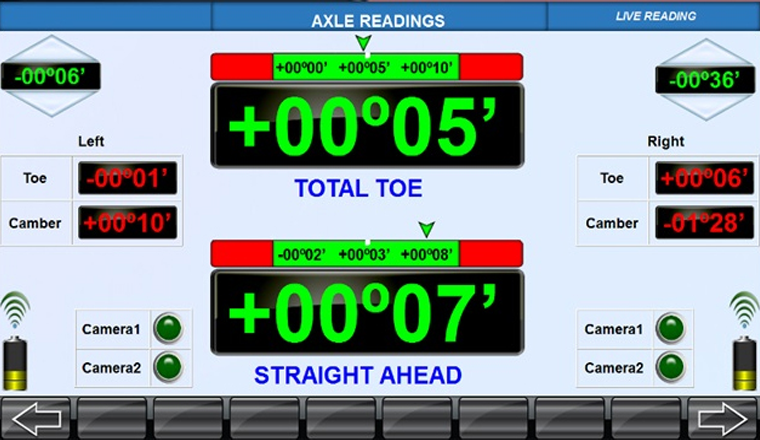

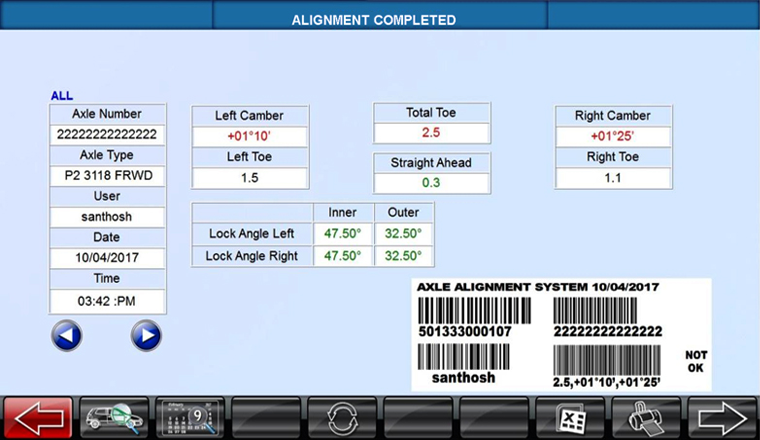

| Individual Toe | ± 30mm | 0.2mm | ± 0.2mm |

| Total Toe-in | ± 60mm | 0.2mm | ± 0.2mm |

| Straight Ahead | ± 60mm | 0.2mm | ± 0.2mm |

| Camber | ± 10° 00' | 00° 02' | ± 00° 02' |

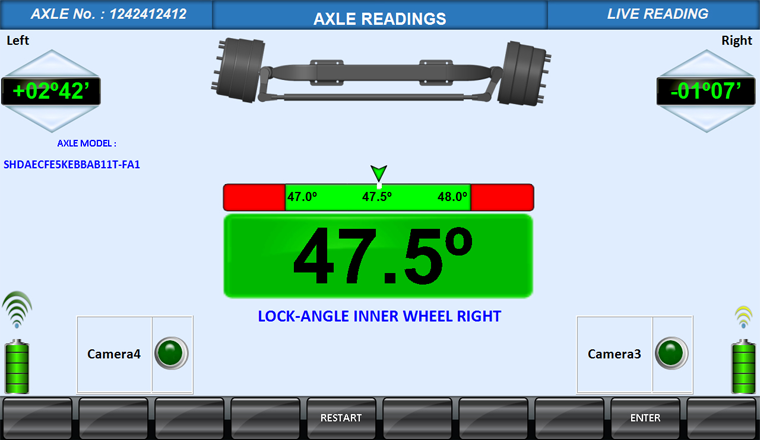

| Lock to Lock Angle | 25° to 55° | 00° 07' | ± 00° 15' |

Manatec Europe BV,

Warandestraat 1A, 9240.

Zele, Belgium.

Phone : +32 492 35 33 40

email : sales@manateceurope.eu